In recent years, smart manufacturing has triggered a new wave of industrial revolution in manufacturing, combining real-time data analysis, artificial intelligence (AI), and machine learning (ML) to achieve high automation, allowing manufacturing production sites to have the ability to self-perceive, self-learn, self-decide, and self-execute. The most basic and important requirement for realizing smart manufacturing is the industrial real-time database used to manage a large amount of operational data.

Generally, industrial big data has six characteristics: large-scale, fast, diverse, authentic, valuable, and visible. Due to these characteristics of industrial big data, the factory's database often needs to store data transmitted from hundreds or thousands of devices in a "second"-level manner to ensure the authenticity and immediacy of the data. Real-time databases are born to support the rapid write, storage, and query of a large amount of operational data in industrial scenarios, and sometimes even involve real-time feedback control.

LEO SYSTEMS,INC. has years of rich experience in the application of smart manufacturing and smart factory introduction, mainly using the "PI (Plant Information) System database system" as a collection of industrial big data, and using the data from this system to connect to equipment failure prediction, process optimization, and other factory AI applications.

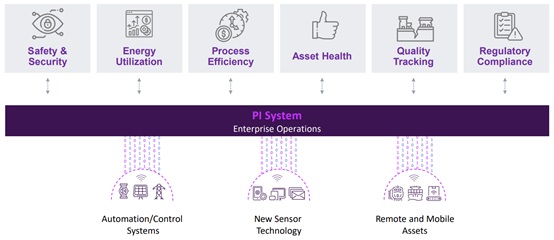

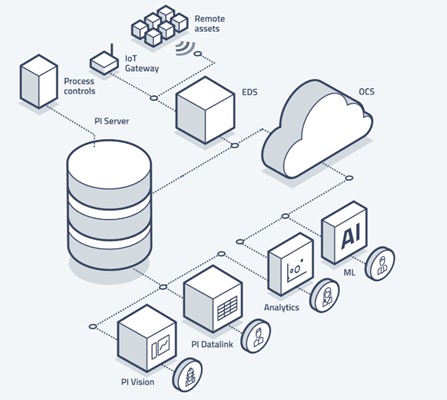

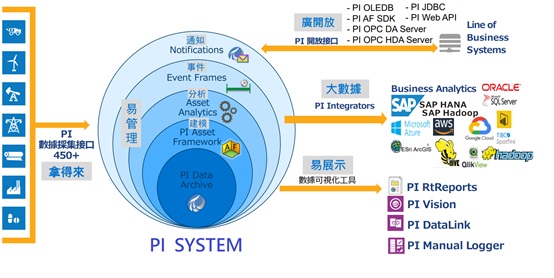

The data storage structure of the PI System database system is a non-relational database that provides continuous historical data or real-time data. The PI System database system can collect, standardize, and store real-time operational data, and maintain the high authenticity of data, giving engineers and on-site operators higher work efficiency and accelerating the work of analysts and data scientists. It can also connect the collected data to many application levels, such as predictive analysis, AI, and machine learning.

The PI System database system can record all types of data, and each different data segment is called a PI Tag. For a given PI tag, it can be recorded as an event or data value over time, and different data can be recorded over time to create a historical data chart that is updated in real-time. Compared with other real-time databases, it also has the following advantages:

- The scale of a single point can reach 4 million points

- The data throughput is 4 million/sec

- The storage capacity is 10-15 thousand events/sec

- The data access capacity is 1 million events/sec

- Patent compression technology and unique secondary filtering technology ensure that the data is not distorted and greatly saves storage space.

- Within seconds, 2-3 years of historical data with 1,000 points can be obtained.

Currently, the PI System database system is widely used in industries such as power, water resources, petroleum, mining, manufacturing, chemical, biotechnology, transportation, and infrastructure.