"Metaverse" was one of the most popular keywords worldwide in 2022, and AR and VR technologies played a crucial role in it. High bandwidth, fast transmission, and computational power are essential elements of the metaverse. In response to this trend, innovative applications of 5G and AI have been developing at an incredible pace. The application of 5G, edge computing, AI, and other technologies has also brought about a wave of smart industrial transformation.

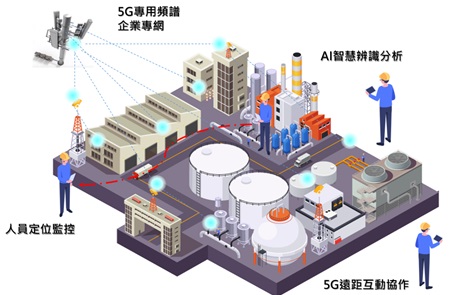

Driven by the trend of smart applications, LEO SYSTEMS,INC. has been investing in the development of an AI integrated platform technology in recent years. In response to the needs of recognizing a large number of instrument data, monitoring factory equipment, and reporting inspection information in petrochemical plants, NARLabs has developed the "LEO SYSTEMS Smart Factory Inspection System". The 5G+AI module upgrades the factory inspection from laborious and time-consuming manual inspections to a cloud-based smart management platform.

|

"LEO SYSTEMS Smart Factory Inspection System"not only integrates machine learning algorithms and a large amount of petrochemical industry big data from IoT devices but also combines analysis data derived from professional practical experience to provide dynamic predictions and various inspection indicators through the AI module. Equipped with an explosion-proof helmet that contains AR glasses, 4K cameras, control chips, 5G communication, and other devices, the inspection personnel's equipment is lightweight, and the inspection is sensorized and automated, aiming to improve their mobility and safety. Furthermore, the innovative AI smart recognition and analysis technology can convert analog images into digital data for dynamic analysis in 2 to 5 seconds, easily solving the problem of remote factory management. With bidirectional audio and video and dynamic guidance, engineers can effectively provide remote guidance to assist on-site personnel in real-time and appropriate processing. By combining 5G smart applications,LEO SYSTEMS,INC.extends the system technology energy through AIoT, improves factory safety, detects crucial data alerts for equipment and facilities, and aims to minimize occupational hazards, helping companies achieve the goals of improving production efficiency and reducing operating costs. |